相关证件:

会员类型:

会员年限:17年

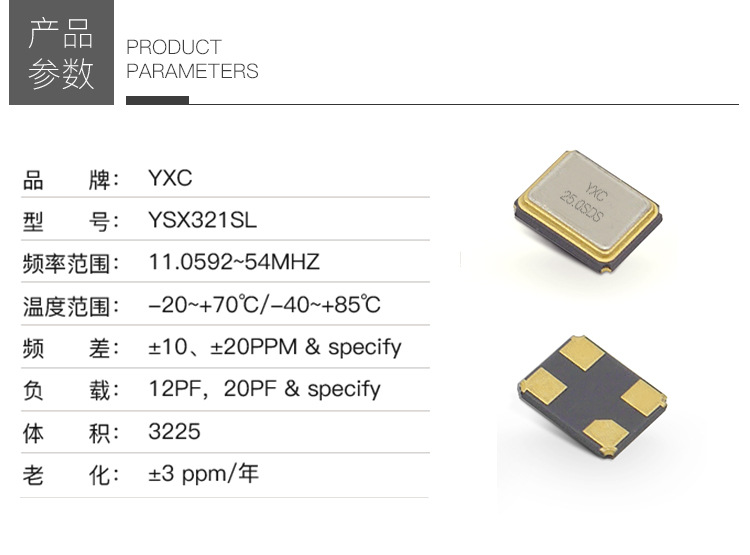

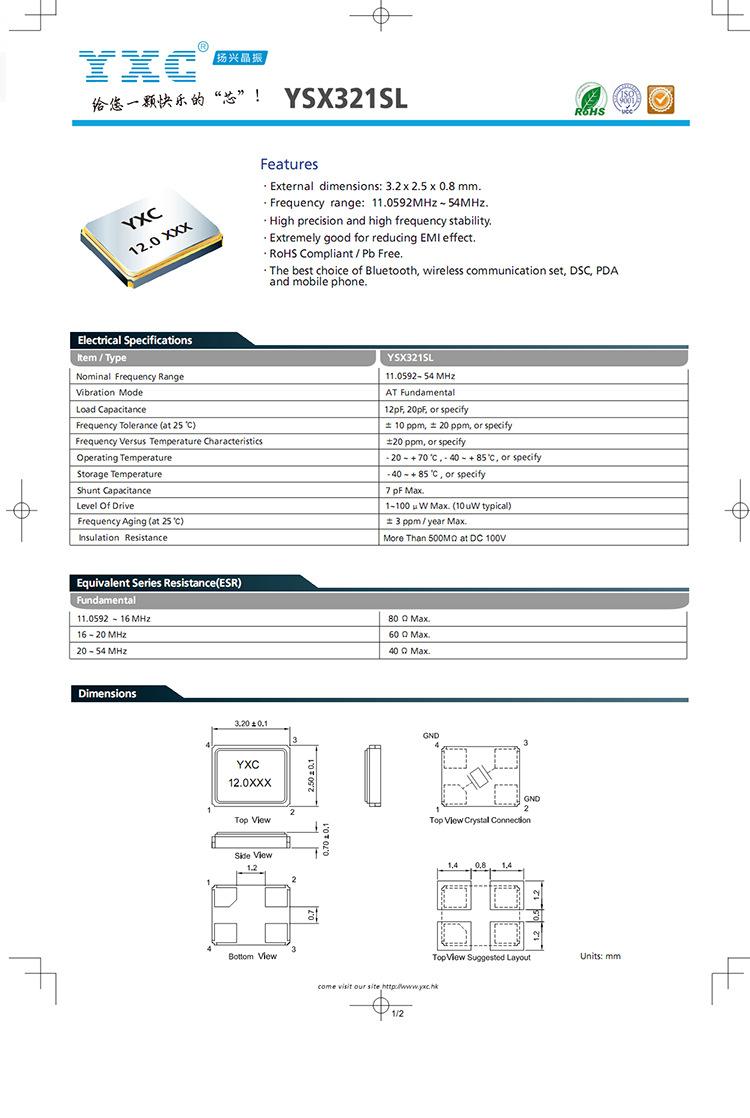

| YSX321SL 3225 4P | |||

| 请点击您需要的参数一起加到购物车,找不到您需要的请联系客服 | |||

| 标准频率 | 负载电容 | 频率偏差 | 点击购买 |

| 12MHZ | 10PF | 10PPM | rel="nofollow" Buy |

| 12MHZ | 12PF | 10PPM | rel="nofollow" Buy |

| 12MHZ | 20PF | 10PPM | rel="nofollow" Buy |

| 14.7456MHZ | 12PF | 10PPM | rel="nofollow" Buy |

| 16MHZ | 18PF | 10PPM | rel="nofollow" Buy |

| 20MHZ | 20PF | 10PPM | rel="nofollow" Buy |

| 24MHZ | 10PF | 10PPM | rel="nofollow" Buy |

| 24MHZ | 12PF | 10PPM | rel="nofollow" Buy |

| 24MHZ | 20PF | 20PPM | rel="nofollow" Buy |

| 25MHZ | 10PF | 10PPM | rel="nofollow" Buy |

| 25MHZ | 12PF | 10PPM | rel="nofollow" Buy |

| 25MHZ | 20PF | 10PPM | rel="nofollow" Buy |

| 26MHZ | 9PF | 10PPM | rel="nofollow" Buy |

| 26MHZ | 10PF | 10PPM | rel="nofollow" Buy |

| 26MHZ | 12PF | 10PPM | rel="nofollow" Buy |

| 27MHZ | 20PF | 10PPM | rel="nofollow" Buy |

| 27.12MHZ | 10PF | 10PPM | rel="nofollow" Buy |

| 30MHZ | 12PF | 10PPM | rel="nofollow" Buy |

| 30MHZ | 20PF | 10PPM | rel="nofollow" Buy |

| 48MHZ | 20PF | 10PPM | rel="nofollow" Buy |

| 54MHZ | 10PF | 10PPM | rel="nofollow" Buy |

| 如您需要购买同类别的其他系列产品,请点击以下链接 | ||

| 产品型号 | 产品规格 | 点击购买 |

| HC-49US | 11.5x4.5x3.68mm | rel="nofollow" Buy |

| HC-49SMD | 11.4x4.8x3.8mm | rel="nofollow" Buy |

| HC-49UM | 11.05x4.65x13.46mm | rel="nofollow" Buy |

| YSX321SL | 3225 4P | rel="nofollow" Buy |

| YSX530GA | 5032 2P | rel="nofollow" Buy |

| YSX531SL | 5032 4P | rel="nofollow" Buy |

| YT-26 | 2060 2P | rel="nofollow" Buy |

| YT-38 | 3080 2P | rel="nofollow" Buy |

| R315 | D11,F11,TO39 | rel="nofollow" Buy |

| R433 | D11,F11,TO39 | rel="nofollow" Buy |

石英晶振压封条件影响

石英晶振平行封焊的因素还有夹具的设计、电极的位置、上盖的质量和上盖与基座的匹配等,另外封焊设备本身的可靠性也是影响封焊质量的因素之一。

夹具孔位的中心与转台中心要一致,夹具夹牢基座,否则焊接过程中电极可能会把基座粘起来;左、右电极位置保持在同一高度和同一水平线上且尽量对称;电极滚轮要定期打磨和更换、否则会影响焊接均匀性;上盖尺寸不能太大或太小,而且拐角有倾角,因为长方形基座的焊接电极与上盖角接触两次,焊接热量会影响焊接效果;采用边缘有倾角的上盖,焊接时错位的可能性会大大减小。

工艺参数的设定要根据各公司的现状而定,只有优化工艺参数,才能提高石英晶振焊接质量。在石英晶振封焊完产品后,对封装过程中出现的现象进行适当的总结,有待封装技术的进一步提高。

真空平行缝焊(真空度在无负载、无封焊动作时可达1.1×10-3Pa),是在短边封焊时加一道抽真空(真空度可达5×10-2Pa),后再封焊,其结果能大大的改善晶体的电阻指标(可下降30~50%),适用于小尺寸、高指标的产品。

平行封焊有半自动机,只完成上盖点焊;滚焊密封由另一台设备完成,中间衔接有人工搬运。全自动机是将真空烘烤、上盖、点焊,滚焊密封、收纳一机完成。